Product

-

Double-roll iron removal dry titanium separation machine type I

-

Double roller iron removal dry titanium separation machine type II

-

Double roller iron removal dry titanium separation machine type III

-

Three-roll iron removal dry titanium separation machine type I

-

Three-roll iron removal dry titanium separation machine type II

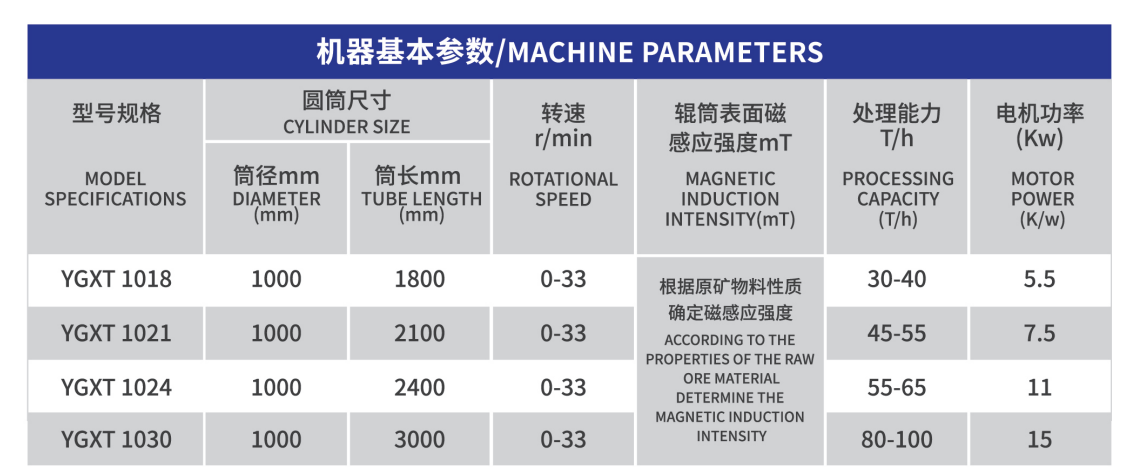

Permanent magnet cylindrical dry type titanium separator

A high-tech enterprise with professional research and development, manufacturing and sales of mining machinery, environmental protection equipment and accessories as the main body. The company has a professional technical team and cooperates with the well-known domestic research institute, the Chinese Academy of Sciences, and independently developed new mineral processing equipment, which saves many mineral processing enterprises. Occupying space, optimizing the process, increasing production capacity and greatly reducing production costs.

Key words:

Permanent magnet cylindrical dry type titanium separator

Classification:

Description

Product Introduction

Magnetic field strength up to 12000 Gauss

The dry titanium ore separator mainly uses high-performance permanent magnets as materials, adopts special manufacturing and installation processes, and has a magnetic field strength as high as 12000 Gauss.

New Technology

Newly upgraded automatic oil injection technology and material distribution technology can perform various mineral selections according to different materials, flexible in use, suitable for the extraction and separation of various weakly magnetic metals such as titanium, manganese, and nickel, and also suitable for the extraction and separation of zirconium and titanium.

Product Advantages

The titanium ore selected by this dry titanium ore separator has high grade and features low power consumption, simple installation, low maintenance rate, high throughput, and high recovery rate. This high-magnetic field permanent magnet titanium ore separator is a patented product of our company.

Main Uses

The permanent magnet cylindrical dry titanium ore separator is mainly used for magnetic separation of weakly magnetic substances such as titanium, manganese, and nickel in granular and powdery materials. It uses dry selection to select titanium, manganese, nickel, and other weakly magnetic substances in the selected materials. It has wide applications in the selection of magnetite, titanium ore, titanomagnetite, hematite, limonite, siderite, chromite, manganese ore, river sand, and other materials enriched with weakly magnetic substances such as titanium, manganese, and nickel.

Product Quality

The quality and function of the product have been consistently praised by customers at home and abroad. The product has also been exported to countries such as Iran, Indonesia, and Mozambique, laying a solid foundation for the good development of the domestic machinery manufacturing industry in the foreign market.

Product Distribution

The product is favored by users in Hebei, Shanxi, Shandong, Gansu, Yunnan, Inner Mongolia, Panzhihua, Sichuan, Xinjiang, Liaoning, and other places due to its high efficiency, energy saving, environmental protection, low price, easy installation, and high safety factor.

Weakly magnetic particles are adsorbed on the surface of the magnetic roller due to the action of magnetic force

Non-magnetic particles are not affected by magnetic force and are thrown into the non-magnetic material hopper under the combined action of gravity and centrifugal force

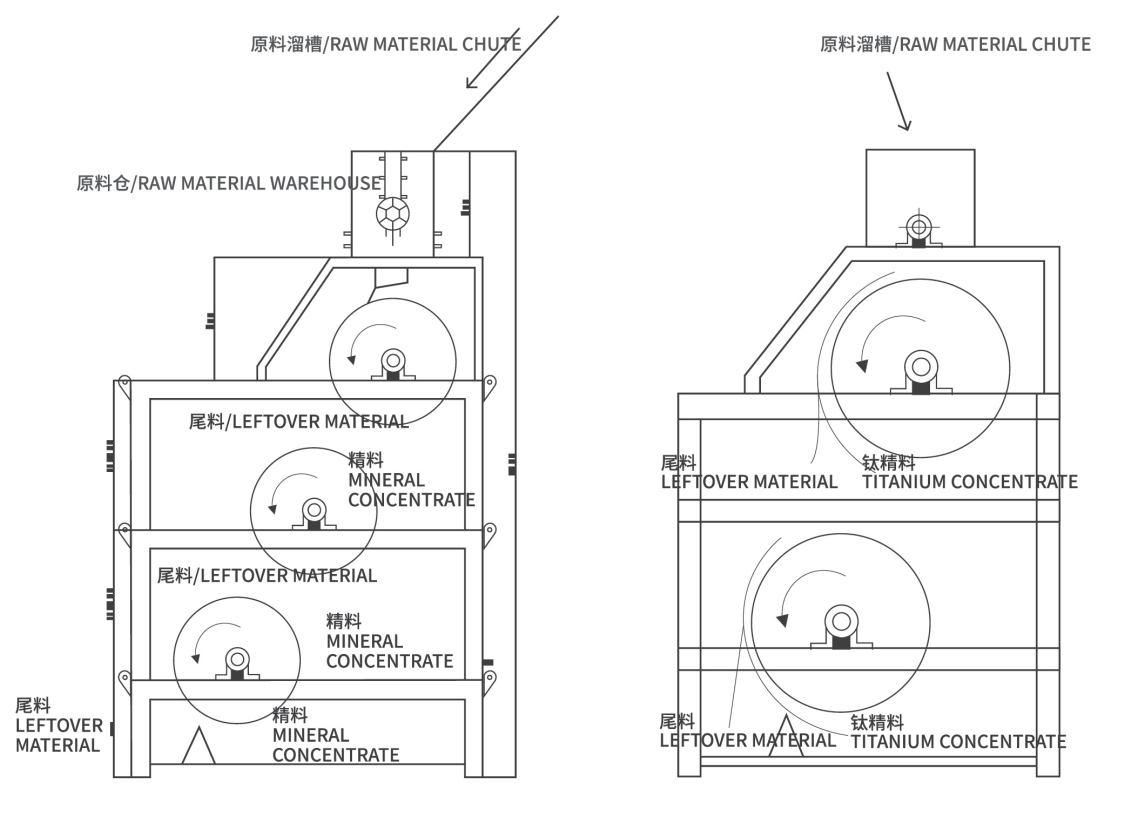

Principle Diagram

Patent Statement

Newly upgraded automatic oil injection technology and material distribution technology can perform various mineral selections according to different materials, flexible in use, suitable for the extraction and separation of various weakly magnetic metals such as titanium, manganese, and nickel, and also suitable for the extraction and separation of zirconium and titanium.

Structural Features

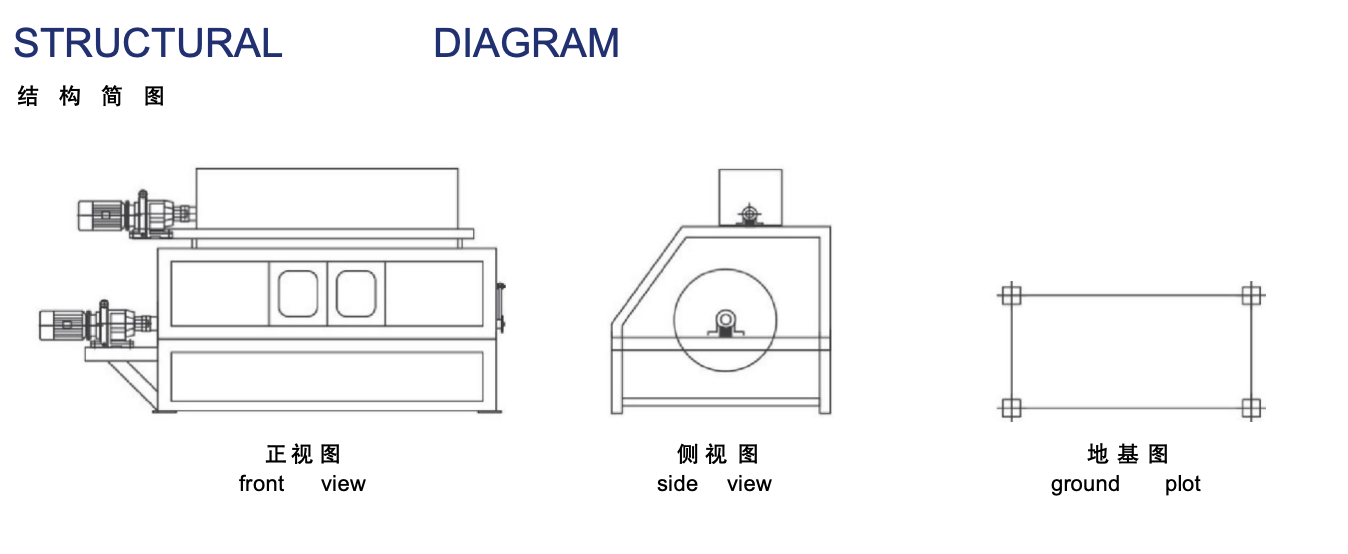

The permanent magnet cylindrical dry titanium ore separator consists of upper and lower frames, permanent magnet rollers, motors, reducers, vibrating feeders, and distribution plates.

The permanent magnet roller is made of special fiber material, and the cylinder surface has a wear-resistant layer. The permanent magnet roller contains a magnetic system.

The magnetic system is the mechanism that generates the magnetic force of the permanent magnet cylindrical dry titanium ore separator, and the magnetic poles are composed of high-performance permanent magnet blocks.

The magnetic system is fixed and does not rotate. The magnetic system angle (the angle between the magnetic pole center line toward the fine powder discharge end and the vertical line) can be adjusted by a wrench fixed on the shaft.

Working Principle

The permanent magnet cylindrical dry titanium ore separator is a weakly magnetic metal separator with a very high magnetic field strength. It has a large product processing capacity, strong adaptability to production fluctuations, and good separation effect. The original ore material enters the vibrating feeder from the hopper and is evenly fed to the magnetic roller through the vibrating feeder. In the process of entering the magnetic field, fine magnetic particles first form magnetic chains and enter the separation space in the form of magnetic chains. Non-magnetic particles are not affected by magnetic force and are thrown into the non-magnetic material hopper under the combined action of gravity and centrifugal force.

Due to the action of magnetic force, magnetic particles, in the high-speed rotating dynamic magnetic field, move along the outer circle of the cylinder and rotate at the same time. The rotation process can break up the formed magnetic chains, magnetic agglomerates, and physical agglomerates. The gangue mixed in them is separated from the magnetic agglomerates during the agglomeration-dispersion-agglomeration-dispersion process and enters the non-magnetic material hopper under the action of gravity and centrifugal force.

Weakly magnetic particles are adsorbed on the surface of the magnetic roller due to the action of magnetic force. The higher the number of rotations of the magnetic particles in the separation space, the more intense the material layer movement, the more times the magnetic agglomerates are broken up, the less gangue is mixed, and the better the separation effect. The motor drives the cylinder, magnetic roller, and brush roller to rotate through a reducer or directly using a stepless speed regulating motor. One or two distribution plates are set below the magnetic roller, and the position of the distribution plate is adjusted by observing and testing the grade of the concentrate.

Roller Patent Technology

After one year of technological innovation, Jupeng successfully developed patented products

Special material roller, this roller has super hard wear resistance, non-heat conduction, high separation rate,

light weight, long service life, easy maintenance, and many other advantages.

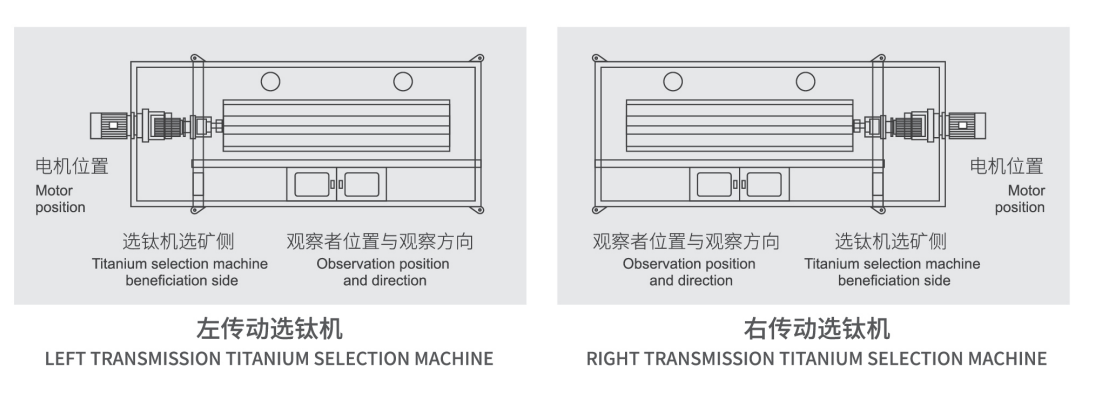

Diagram and features of left and right transmission of permanent magnet cylindrical titanium ore separator

Vibration Feeding Design

The vibrating feeder developed by Jupeng can electronically adjust the vibration frequency to make the original ore material evenly cover the surface of the magnetic roller, greatly improving the recovery efficiency of weakly magnetic metals. At the same time, customers can also adjust the feeding amount of the original ore material according to their own needs to maintain stable feeding.

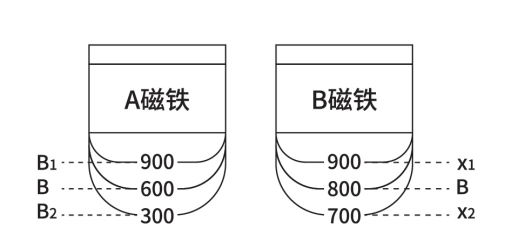

New Concept of Magnetic Circuit Design

Jupeng products all use specially made high-coercivity magnetic materials to make the magnetic system, and high-coercivity magnetic materials have

high-gradient magnetic field, which can better attract weakly magnetic metal substances. The structure of the multi-pole magnetic system effectively increases the number of magnetic reversals, which is more conducive to the discharge of non-magnetic impurities. Coupled with special processes and large-angle magnetic circuit design, the product not only has long-term stability, but also increases the recovery rate of weakly magnetic metals, and the demagnetization does not exceed 5% within 10 years.

Application

Experiment on Separation of Zirconium and Titanium in Dry Separation of Mosan Mine

Experiment on Separation of Zirconium and Titanium in Dry Separation of Mosan Mine

Shandong Yuxiao Site Installation and Production Chart

Shandong Yuxiao Site Installation and Production Chart

Site Installation Drawing

Site Installation Drawing

Site Installation Drawing

Site Installation Drawing

Pre

Type I Twin-Roll Dry Magnetic Separation and Titanium Selection Integrated Machine

Related Products

Consultation

Please leave your contact information, we will provide you with the latest product quotation information