Product

-

Double-roll iron removal dry titanium separation machine type I

-

Double roller iron removal dry titanium separation machine type II

-

Double roller iron removal dry titanium separation machine type III

-

Three-roll iron removal dry titanium separation machine type I

-

Three-roll iron removal dry titanium separation machine type II

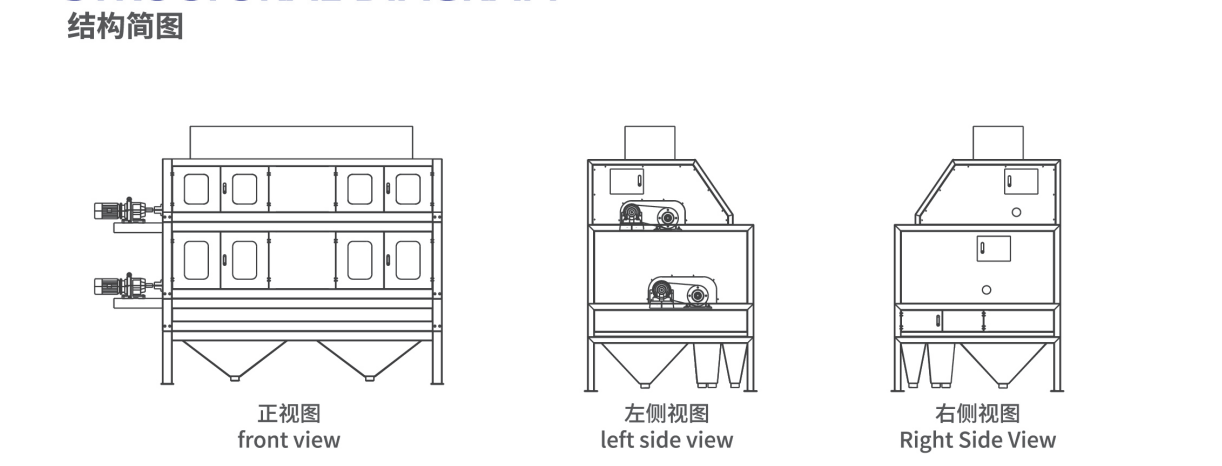

Type II Twin-Roll Dry Magnetic Separation and Titanium Selection Integrated Machine

A high-tech enterprise with professional research and development, manufacturing and sales of mining machinery, environmental protection equipment and accessories as the main body. The company has a professional technical team and cooperates with the well-known domestic research institute, the Chinese Academy of Sciences, and independently developed new mineral processing equipment, which saves many mineral processing enterprises. Occupying space, optimizing the process, increasing production capacity and greatly reducing production costs.

Key words:

Type II Twin-Roll Dry Magnetic Separation and Titanium Selection Integrated Machine

Description

Product Introduction

Magnetic field strength up to 12000 Gauss

Dry titanium ore concentrators mainly use high-performance permanent magnets as materials, manufactured and installed using special manufacturing processes, with a magnetic field strength of up to 12000 Gauss. Equipment can be customized according to customer needs.

New Technology

Newly upgraded automatic oil injection technology and material feeding technology can perform various mineral selections based on different materials. It offers flexible usability and is suitable for the extraction and separation of various weakly magnetic metals such as titanium, manganese, and nickel, and is also suitable for the extraction and separation of zirconium and titanium.

Product Advantages

This dry titanium ore concentrator produces high-grade products. Using large-angle technology, it features low power consumption, simple installation, low maintenance rate, high recovery rate, and high throughput. ( Approximately the throughput of ordinary equipment 3 times ) , stable performance, and good separation effect. ( Material separation, one-step in place ) , small footprint, and low failure rate. The equipment is also equipped with automatic oil injection technology, saving labor and costs for customers while better ensuring the long-term automated operation of the equipment. Equipment can be customized according to customer needs. This high-magnetic field permanent magnet titanium ore concentrator is a patented product of our company.

Main Uses

Product Applications

Suitable for the primary and secondary concentrators of imported ores such as sea sand mines, Mozambique mines, South African mines, Australian mines, Indonesian mines, Madagascar mines, Sierra Leone mines, and Kazakhstan mines. It uses dry selection to extract weakly magnetic substances such as titanium, manganese, and nickel from the selected materials. It has wide applications in the concentration of weakly magnetic substances such as titanium, manganese, and nickel in iron ore, titanium concentrate, titanomagnetite, hematite, limonite, goethite, chromite, manganese ore, and river sand.

Product Quality

The quality and function of the product have been consistently praised by customers at home and abroad. The product has also been exported to countries such as Iran, Indonesia, and Mozambique, laying a solid foundation for the good development of the domestic machinery manufacturing industry in the international market.

Product Distribution

The product is popular in Hebei, Shanxi, Shandong, Gansu, Yunnan, Inner Mongolia, Panzhihua, Sichuan, Xinjiang, and Liaoning, due to its high efficiency, energy saving, environmental protection, low cost, easy installation, and high safety factor.

Application

Experiment on Separation of Zirconium and Titanium in Dry Separation of Mosan Mine

Experiment on Separation of Zirconium and Titanium in Dry Separation of Mosan Mine

Shandong Yuxiao Site Installation and Production Chart

Shandong Yuxiao Site Installation and Production Chart

Site Installation Drawing

Site Installation Drawing

Site Installation Drawing

Site Installation Drawing

Related Products

Consultation

Please leave your contact information, we will provide you with the latest product quotation information