Product

-

Double-roll iron removal dry titanium separation machine type I

-

Double roller iron removal dry titanium separation machine type II

-

Double roller iron removal dry titanium separation machine type III

-

Three-roll iron removal dry titanium separation machine type I

-

Three-roll iron removal dry titanium separation machine type II

Three-roll dry magnetic separation and titanium selection integrated machine Type II

A high-tech enterprise with professional research and development, manufacturing and sales of mining machinery, environmental protection equipment and accessories as the main body. The company has a professional technical team and cooperates with the well-known domestic research institute, the Chinese Academy of Sciences, and independently developed new mineral processing equipment, which saves many mineral processing enterprises. Occupying space, optimizing the process, increasing production capacity and greatly reducing production costs.

Key words:

Three-roll dry magnetic separation and titanium selection integrated machine Type II

Classification:

Description

Main Use

Magnetic field strength up to 12000 Gauss

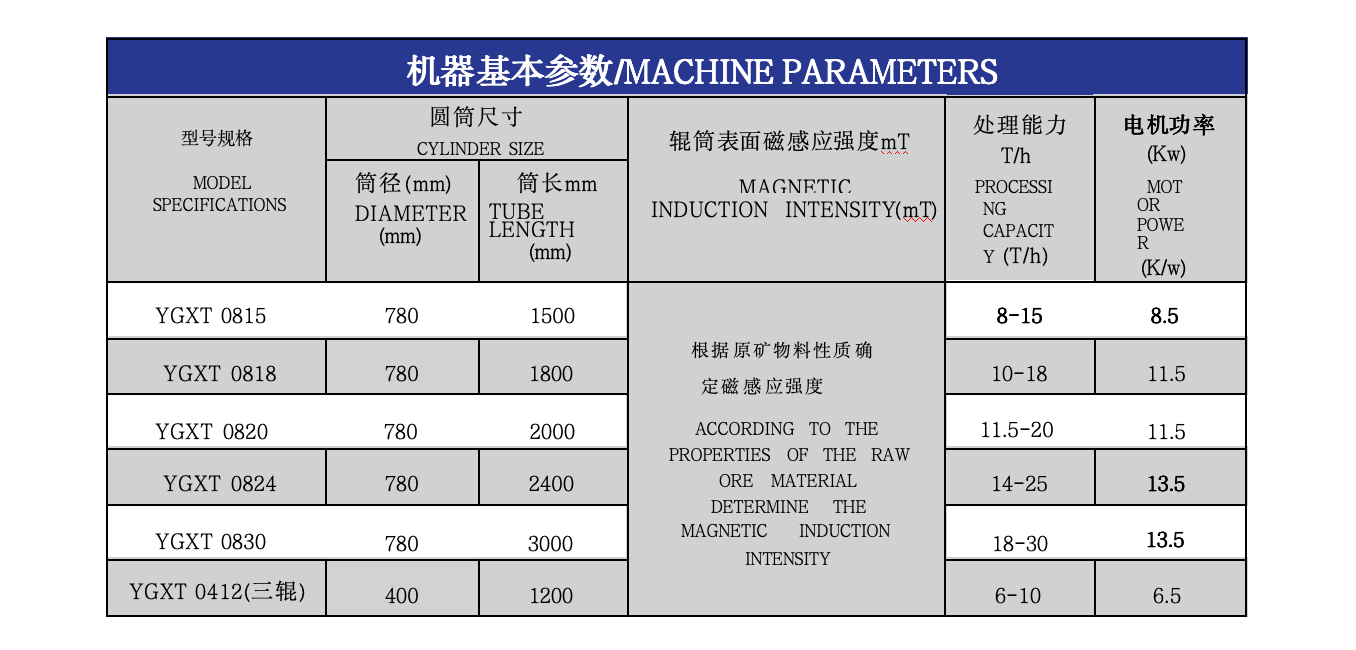

Dry titanium ore separator mainly uses high-performance permanent magnets as materials, adopts special manufacturing and installation processes, and has a magnetic field strength of up to 12000 Gauss. Equipment can be customized according to customer needs.

Newly upgraded automatic oil injection technology and material feeding technology can perform various mineral selections according to different materials. It offers flexible usability and is suitable for the extraction and separation of various weakly magnetic metals such as titanium, manganese, and nickel. It is also suitable for the extraction and separation of zirconium and titanium.

Product Advantages

Suitable for the re-selection and purification of various titanium powders. It adopts a large included angle technology and has a large processing capacity. ( Approximately the processing capacity of ordinary equipment 3 times ), Stable performance and good separation effect ( Material separation, one-step completion ), Features include small footprint and low failure rate. This equipment is also equipped with automatic oil injection technology, saving manpower and costs for customers while better ensuring the long-term automated operation of the equipment. Equipment can be customized according to customer needs.

Main Use

Product Use

Mainly used for magnetic separation of weakly magnetic substances such as titanium, manganese, and nickel in granular and powdery materials, and re-selection and purification of various titanium powders. It uses dry selection to select weakly magnetic substances such as titanium, manganese, and nickel from the selected materials. It has wide applications in the selection of magnetite, titanium ore, titanomagnetite, hematite, limonite, goethite, chromite, manganese ore, river sand, etc., which are rich in weakly magnetic substances such as titanium, manganese, and nickel.

Product Quality

The quality and function of the product have been consistently praised by customers at home and abroad. This product has also been exported to countries such as Iran, Indonesia, and Mozambique, laying a solid foundation for the good development of China's machinery manufacturing industry in the international market.

Product Distribution

The product is popular in Hebei, Shanxi, Shandong, Gansu, Yunnan, Inner Mongolia, Panzhihua, Sichuan, Xinjiang, and Liaoning, and is favored by users for its high efficiency, energy saving, environmental protection, low price, easy installation, and high safety factor.

Technical Features

Dry separation: No water source is required. Separation is achieved through centrifugal force and gravity, suitable for water-scarce areas or scenarios where wet processing needs to be avoided.

Step-by-step purification: Three magnetic rollers form a separation gradient, gradually improving the grade of titanium iron ore, allowing for one-step separation with only one piece of equipment.

Energy-saving and environmentally friendly: Using a permanent magnet design, it has low energy consumption and no wastewater discharge, meeting the needs of green ore dressing.

Application Scenarios and Advantages

Titanium iron ore beneficiation: Especially suitable for the treatment of vanadium-titanium magnetite tailings in places like Panzhihua. It can effectively recover coarse-grained titanium iron ore and remove iron impurities.

Wide adaptability: In addition to titanium iron ore, it can also process weakly magnetic minerals such as manganese ore and chromite, as well as metal recovery from electronic waste.

Easy maintenance: Modular design supports quick replacement of magnetic rollers, reducing downtime.

Application

Experiment on Separation of Zirconium and Titanium in Dry Separation of Mosan Mine

Experiment on Separation of Zirconium and Titanium in Dry Separation of Mosan Mine

Shandong Yuxiao Site Installation and Production Chart

Shandong Yuxiao Site Installation and Production Chart

Site Installation Drawing

Site Installation Drawing

Site Installation Drawing

Site Installation Drawing

Related Products

Consultation

Please leave your contact information, we will provide you with the latest product quotation information