Product

-

Double-roll iron removal dry titanium separation machine type I

-

Double roller iron removal dry titanium separation machine type II

-

Double roller iron removal dry titanium separation machine type III

-

Three-roll iron removal dry titanium separation machine type I

-

Three-roll iron removal dry titanium separation machine type II

Permanent magnet cylindrical wet type titanium ore separator

A high-tech enterprise with professional research and development, manufacturing and sales of mining machinery, environmental protection equipment and accessories as the main body. The company has a professional technical team and cooperates with the well-known domestic research institute, the Chinese Academy of Sciences, and independently developed new mineral processing equipment, which saves many mineral processing enterprises. Occupying space, optimizing the process, increasing production capacity and greatly reducing production costs.

Key words:

Permanent magnet cylindrical wet type titanium ore separator

Classification:

Description

Product Introduction

Magnetic field strength up to 12000 Gauss

The wet-type titanium ore separator mainly uses high-performance permanent magnets as materials and is manufactured and installed using special manufacturing processes. The wet-type titanium ore separator can replace a large number of spirals, saving a large amount of water, with a magnetic field strength up to 12000 Gauss.

New Technology

The newly upgraded material separation technology can perform various mineral separations according to different materials, offering flexible usability and suitability for the extraction and separation of various weakly magnetic metals such as titanium, manganese, and nickel, as well as for the extraction and separation of zirconium and titanium.

Product Advantages

The titanium ore separated by this wet-type titanium ore separator has high grade and features low power consumption, simple installation, low maintenance rate, high throughput, and high recovery rate. This high-magnetic field permanent magnetic titanium ore separator is a patented product of our company.

Technical Features

1. Wet separation: Using water as the medium, suitable for fine-grained mineral separation, reducing dust pollution, and being environmentally friendly and efficient.

2. Permanent magnet design: Using high-performance permanent magnets, the magnetic field is stable and energy-saving, without the need for additional electrical energy to maintain the magnetic field.

3. Cylindrical structure: The design of automatic separation of the rotating magnetic cylinder and non-magnetic minerals enables strong continuous operation capability and convenient maintenance.

Main Applications

Product Applications

1. Ilmenite separation: Efficiently extracting titanium concentrate from native ilmenite or associated ores, improving titanium grade, and removing non-magnetic impurities such as quartz and feldspar.

2. Placer processing: Suitable for titanium resources such as beach placers, separating titanium minerals from gangue such as silicates and garnets.

3. Tailings re-selection: Re-processing historical tailings or tailings from existing ore dressing processes to recover residual titanium minerals and reduce resource waste.

4. Smelting slag processing: Recovering titanium components from titanium-containing smelting slag to achieve comprehensive resource utilization.

In iron ore or polymetallic ore beneficiation, separating coexisting titanium minerals to improve comprehensive utilization, such as titanium recovery from vanadium-titanium magnetite.

Technical Features

1. Wet separation: Using water as the medium, suitable for fine-grained mineral separation, reducing dust pollution, and being environmentally friendly and efficient.

2. Permanent magnet design: Using high-performance permanent magnets, the magnetic field is stable and energy-saving, without the need for additional electrical energy to maintain the magnetic field.

3. Cylindrical structure: The design of automatic separation of the rotating magnetic cylinder and non-magnetic minerals enables strong continuous operation capability and convenient maintenance.

Product Distribution

Products are distributed in Hebei, Shanxi, Shandong, Gansu, Yunnan, Inner Mongolia, Sichuan, Panzhihua, Xinjiang, Liaoning, etc., and are favored by a large number of users for their high efficiency, energy saving, environmental protection, low price, easy installation, high safety factor, and many other advantages. 的青睐。

Working Principle

永 磁 筒式 湿式选 钛 机是 采用 永 磁 材 料 作 为 磁 源。 矿浆 经 湿 式 选 钛 机 给 矿 箱 流 入 槽 体 后, 在 给 矿 喷 水 管 Under the action of the water flow from the water spray pipe, the ore particles enter the ore feeding area of the tank body in a loose state.

Under the action of the magnetic field, the ore with stronger magnetism undergoes magnetic aggregation to form "magnetic clusters" or "magnetic chains", which are adsorbed on the surface of the roller. The "magnetic clusters" or “ 磁 链” 随 辊 筒 旋 转 翻 转 过 程中, are taken out 磁 of the field area and 冲 洗 水 冲 入 精 矿 in the washing and concentrating tank, non 磁 Sex Or Weak 磁 Sex 矿 料 By Left 在 Discharged from the pulp trough with the pulp, completing the selection.

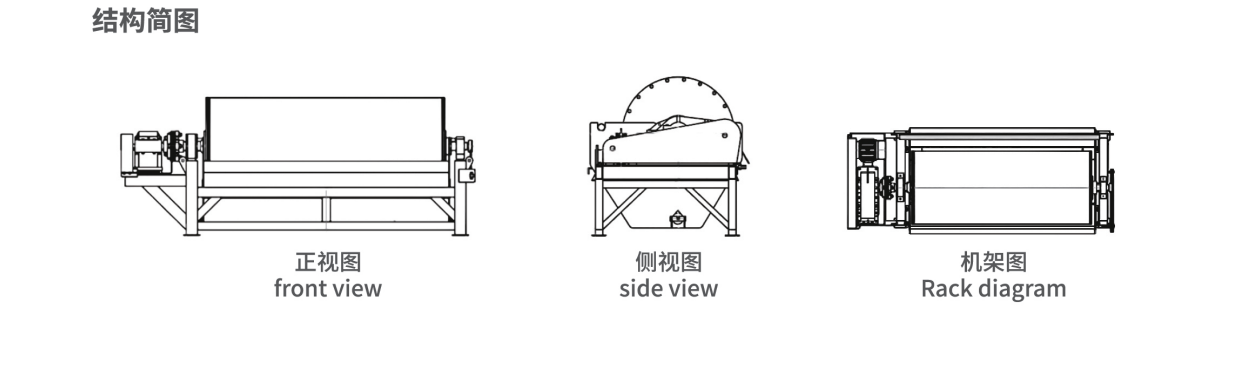

Working principle diagram

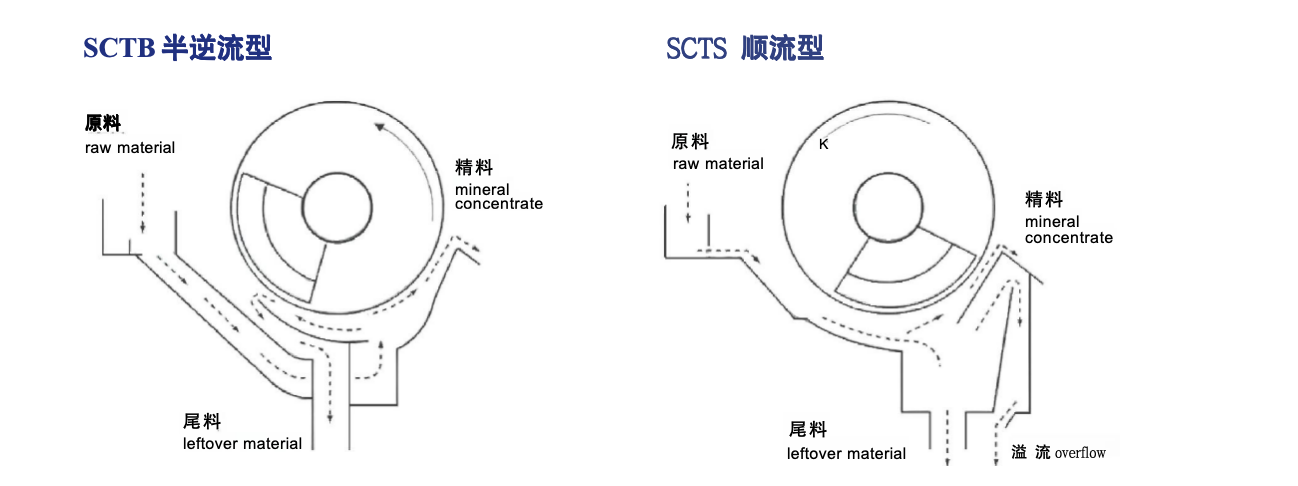

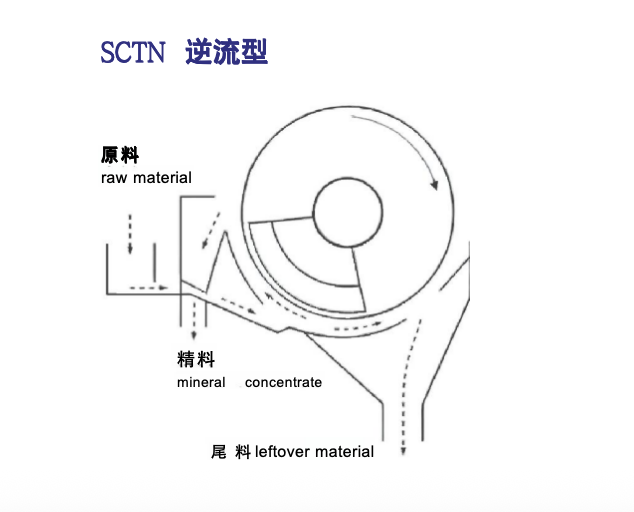

Three Types of flume characteristics

1. Half 1. Countercurrent flume is suitable for rough and fine selection of ores with a particle size of 0.5~0mm, especially for fine selection of minerals with a particle size of 0.15~0mm

2. Concurrent flume is suitable for rough and fine selection of ores with a particle size of 6~0mm

3. Countercurrent flume is suitable for rough and fine selection of ores with a particle size of 0.6~0mm

Structural characteristics

Patent statement

Newly upgraded automatic oil injection technology and material distribution technology. It can perform various mineral selections according to different materials, with flexible usability. It is suitable for the extraction and separation of various weakly magnetic metals such as titanium, manganese, and nickel, and is also suitable for the extraction and separation of zirconium and titanium.

Application

Experiment on Separation of Zirconium and Titanium in Dry Separation of Mosan Mine

Experiment on Separation of Zirconium and Titanium in Dry Separation of Mosan Mine

Shandong Yuxiao Site Installation and Production Chart

Shandong Yuxiao Site Installation and Production Chart

Site Installation Drawing

Site Installation Drawing

Site Installation Drawing

Site Installation Drawing

Related Products

Consultation

Please leave your contact information, we will provide you with the latest product quotation information