Product

-

Double-roll iron removal dry titanium separation machine type I

-

Double roller iron removal dry titanium separation machine type II

-

Double roller iron removal dry titanium separation machine type III

-

Three-roll iron removal dry titanium separation machine type I

-

Three-roll iron removal dry titanium separation machine type II

Three-roll dry magnetic separation and titanium selection integrated type I

A high-tech enterprise with professional research and development, manufacturing and sales of mining machinery, environmental protection equipment and accessories as the main body. The company has a professional technical team and cooperates with the well-known domestic research institute, the Chinese Academy of Sciences, and independently developed new mineral processing equipment, which saves many mineral processing enterprises. Occupying space, optimizing the process, increasing production capacity and greatly reducing production costs.

Key words:

Three-roll dry magnetic separation and titanium selection integrated type I

Classification:

Description

Product Introduction

Magnetic field strength up to 12000 Gauss

Dry titanium ore separator mainly uses high-performance permanent magnet materials, adopts special manufacturing and installation processes, and has a magnetic field strength of up to 12000 Gauss. Equipment can be customized according to customer needs.

New Technology

Newly upgraded automatic oil injection technology and material distribution technology. It can perform various mineral selections based on different materials, offering flexible usability and suitability for the extraction and separation of various weakly magnetic metals such as titanium, manganese, and nickel. It is also suitable for the extraction and separation of zirconium and titanium.

Product Advantages

This dry titanium ore separator produces high-grade products and features low power consumption, simple installation, low maintenance rate, high throughput, and high recovery rate. This high-magnetic field permanent magnet titanium ore separator is a patented product of our company.

Working Principle

The three-roller deironing dry titanium ore separator is a highly efficient equipment combining magnetic separation and mineral separation functions, mainly used for deironing and beneficiation of titanium-containing minerals in a dry state ( such as ilmenite ) The working principle is mainly based on the combination of magnetic and gravity separation technologies, achieving the separation goal through the synergistic effect of three magnetic rollers.

The three magnetic rollers undertake different separation tasks in sequence: the first magnetic roller is mainly used for the initial adsorption of strongly magnetic iron impurities; the subsequent two magnetic rollers gradually separate weakly magnetic ilmenite and other useful minerals by adjusting the magnetic field strength or separation angle.

The mineral raw materials to be processed are evenly distributed to the surface of the first-stage magnetic roller through a vibrating feeder. At this time, strongly magnetic substances ( such as iron filings and magnetite ) are adsorbed on the surface of the roller, while non-magnetic or weakly magnetic minerals ( such as ilmenite ) fall down to the next separation area under the action of gravity.

The material enters the second magnetic roller, where the magnetic field strength may be slightly lower or the separation angle adjusted to enhance the adsorption capacity of weakly magnetic ilmenite. The third magnetic roller further refines the separation to ensure the purity of ilmenite. The ilmenite adsorbed on the magnetic roller rotates with the roller to the ( such as quartz and feldspar ) are not affected by the magnetic field throughout the process and are directly discharged via a conveyor belt.

Patent Statement

Newly upgraded automatic oil injection technology and material distribution technology. It can perform various mineral selections based on different materials, offering flexible usability and suitability for the extraction and separation of various weakly magnetic metals such as titanium, manganese, and nickel. It is also suitable for the extraction and separation of zirconium and titanium.

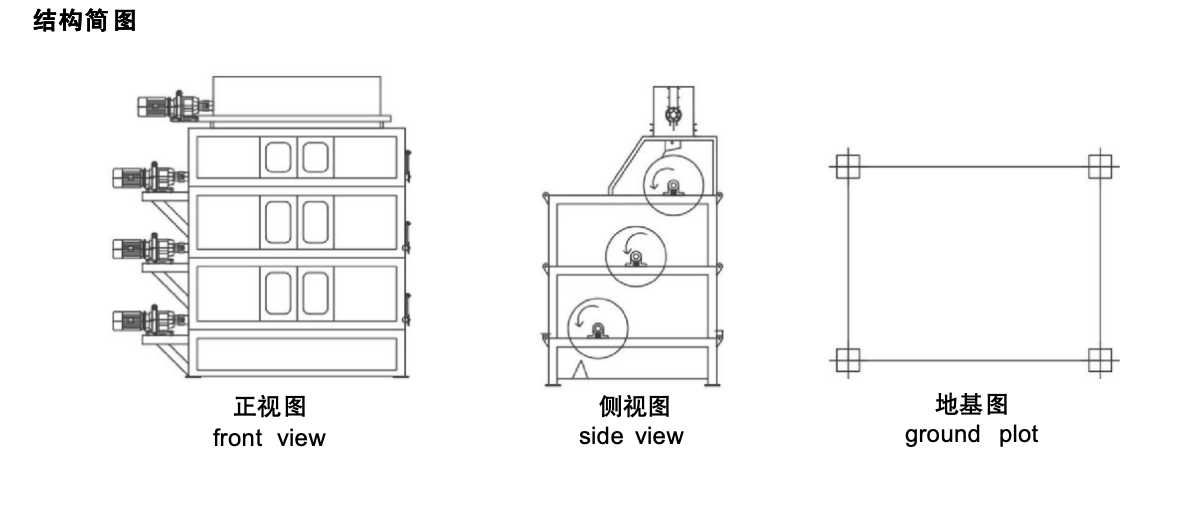

Structural Features

The permanent magnet cylindrical dry titanium ore separator consists of upper and lower frames, permanent magnet rollers, motors, reducers, vibrating feeders, and distribution plates.

The permanent magnet roller is made of special fiber material with a wear-resistant layer on the surface. The permanent magnet roller contains a magnetic system.

The magnetic system is the mechanism that generates the magnetic force in the permanent magnet cylindrical dry titanium ore separator, and the magnetic poles are composed of high-performance permanent magnet blocks.

The magnetic system is fixed and does not rotate, with a magnetic system offset angle of ( The angle between the magnetic pole centerline toward the fine powder discharge end and the vertical line ) can be adjusted using a wrench fixed on the shaft.

Features of Jupeng Permanent Magnet Cylindrical Titanium Ore Separator

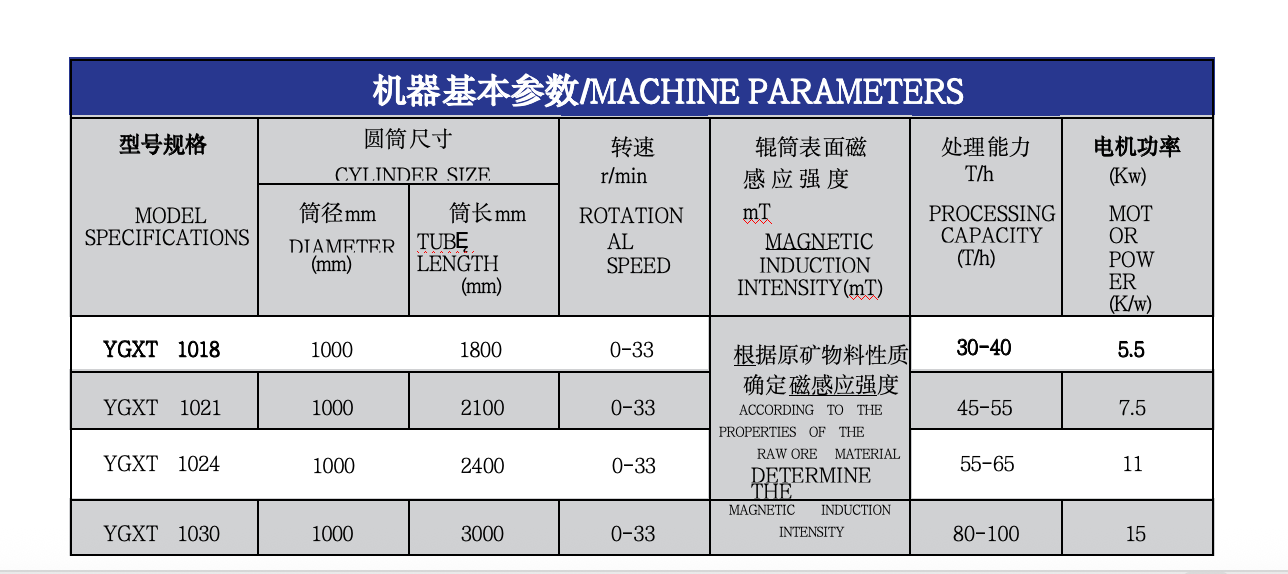

Based on the characteristics, composition, and grade of the original ore, Jupeng designs various permanent magnet cylindrical titanium ore separators for customers at different separation stages, including dry titanium ore separators, double-roller titanium ore separators, three-roller titanium ore separators, and wet titanium ore separators.

01 Safe and Durable

It uses specially customized neodymium iron boron magnetic materials, which have high remanence and high coercivity. It also uses galvanized protective treatment, and the magnetic materials are fixed to the magnetic yoke plate with stainless steel screws to ensure that the magnetic materials will never fall off or be damaged.

02 New Technology

The roller is made of special materials and ultra-hard wear-resistant ceramic pieces integrated and solidified, which is a Jupeng patented product. It has many advantages such as ultra-hard wear resistance, no heat generation, high separation rate, light weight, long service life, and easy maintenance, and is safe, reliable, dustproof, and moisture-proof.

03 Discharge Washing

The duckbill-shaped water pipe has a high jet speed, which is conducive to discharge washing and prevents the water pipe from being blocked by impurities.

04 Scientific Design

It adopts a scientific magnetic circuit design, a multi-pole structure, uniform magnetic force distribution, large magnetic field action depth, good separation effect, high recovery rate, large throughput, and significant grade improvement.

05 Personalized Customization

The tank structure is reasonable, and the tank can be customized according to customer requirements to meet customers' personalized needs.

06 Efficient and Reliable

The transmission device is efficient, safe, stable, and reliable. The machine has good overall performance and can operate for a long time without failure.

Application

Experiment on Separation of Zirconium and Titanium in Dry Separation of Mosan Mine

Experiment on Separation of Zirconium and Titanium in Dry Separation of Mosan Mine

Shandong Yuxiao Site Installation and Production Chart

Shandong Yuxiao Site Installation and Production Chart

Site Installation Drawing

Site Installation Drawing

Site Installation Drawing

Site Installation Drawing

Related Products

Consultation

Please leave your contact information, we will provide you with the latest product quotation information