Product

-

Double-roll iron removal dry titanium separation machine type I

-

Double roller iron removal dry titanium separation machine type II

-

Double roller iron removal dry titanium separation machine type III

-

Three-roll iron removal dry titanium separation machine type I

-

Three-roll iron removal dry titanium separation machine type II

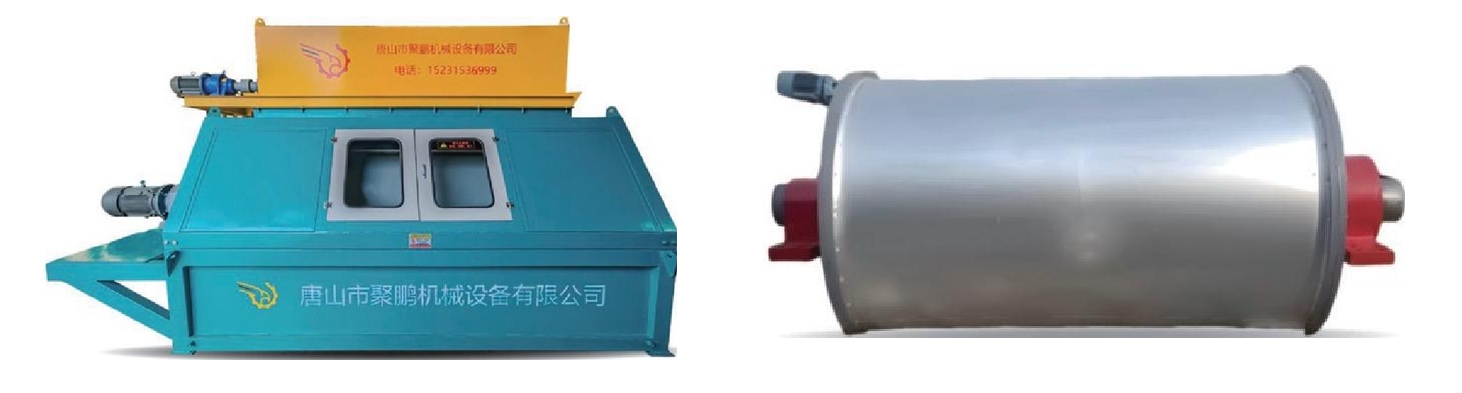

Permanent magnet dry magnetic separator (magnetic pulley)

A high-tech enterprise with professional research and development, manufacturing and sales of mining machinery, environmental protection equipment and accessories as the main body. The company has a professional technical team and cooperates with the well-known domestic research institute, the Chinese Academy of Sciences, and independently developed new mineral processing equipment, which saves many mineral processing enterprises. Occupying space, optimizing the process, increasing production capacity and greatly reducing production costs.

Key words:

Permanent magnet dry magnetic separator (magnetic pulley)

Classification:

Description

Scope of application

The permanent magnet dry magnetic separator (magnetic pulley) is a low-cost, high-efficiency, and durable energy-saving and environmentally friendly mineral processing equipment. The magnetic system is made of neodymium iron boron material with high remanence and high coercivity. It can also be customized with different magnetic induction intensities according to customer's specific needs. The product is widely used in ore dressing plants, iron mines, steel plants, building material recycling and other industries. It features low energy consumption, high recovery rate, large processing capacity, small footprint, and high utilization rate.

Technical features

1. Uniform: With a forced feeding device to achieve uniform ore feeding.

2. Magnetic system: The magnetic system adopts a large included angle design, up to 270 degrees. Multi-pole design, and the magnetic system structure can be changed according to the mineral properties and the requirements of beneficiation index to achieve reasonable beneficiation index.

3. Magnetic field: A magnetic field stirring device is set inside the cylinder.

4. Ore unloading: High-performance stainless steel scraper two-stage unloading is adopted to ensure clean unloading.

Basic machine parameters |

||||||

Model specifications |

Cylinder diameter mm |

Cylinder length mm |

Belt width r/min |

Cylinder surface magnetic Induction intensity mT |

Feed size mm |

Processing capacity t/h |

CTG-50/50 |

500 |

600 |

500 |

Root According Original Ore Material Material Property Quality Confirm Fixed Magnetic Feeling Should Strong Degree |

≤50 |

70-120 |

CTG-50/65 |

500 |

750 |

650 |

≤50 |

70-150 |

|

CTG-63/65 |

630 |

750 |

650 |

≤50 |

100-160 |

|

CTG-50/80 |

500 |

950 |

800 |

≤50 |

120-200 |

|

CTG-63/80 |

630 |

950 |

800 |

≤150 |

130-180 |

|

CTG-80/80 |

800 |

950 |

1000 |

≤150 |

150-260 |

|

CTG-63/100 |

630 |

1150 |

1000 |

≤150 |

180-300 |

|

CTG-80/100 |

630 |

1150 |

1000 |

≤150 |

150-240 |

|

CTG-63/120 |

100 |

1150 |

1200 |

≤250 |

180-350 |

|

CTG-80/120 |

630 |

1400 |

1200 |

≤150 |

150-240 |

|

CTG-100/120 |

800 |

1400 |

1200 |

≤150 |

180-350 |

|

CTG-120/120 |

1000 |

1400 |

1200 |

≤250 |

200-400 |

|

CTG-80/140 |

1200 |

1400 |

1400 |

≤250 |

220-0 |

|

CTG-100/140 |

800 |

1600 |

1400 |

≤250 |

240-400 |

|

CTG-100/140 |

1000 |

1600 |

1400 |

≤250 |

260-450 |

|

CTG-120/1410 |

1200 |

1600 |

1400 |

≤300 |

280-50 |

|

CTG-140/140 |

1400 |

1600 |

1400 |

≤350 |

300-50 |

|

Application

Experiment on Separation of Zirconium and Titanium in Dry Separation of Mosan Mine

Experiment on Separation of Zirconium and Titanium in Dry Separation of Mosan Mine

Shandong Yuxiao Site Installation and Production Chart

Shandong Yuxiao Site Installation and Production Chart

Site Installation Drawing

Site Installation Drawing

Site Installation Drawing

Site Installation Drawing

Related Products

Consultation

Please leave your contact information, we will provide you with the latest product quotation information