Product

-

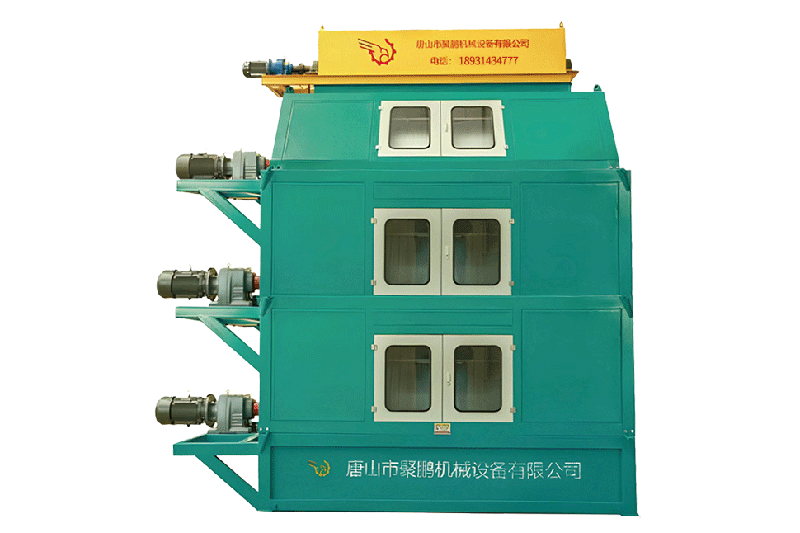

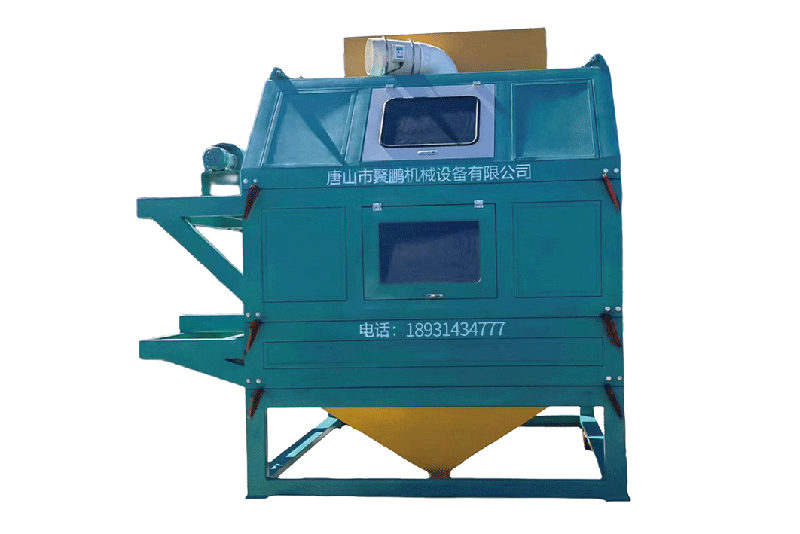

Double-roll iron removal dry titanium separation machine type I

-

Double roller iron removal dry titanium separation machine type II

-

Double roller iron removal dry titanium separation machine type III

-

Three-roll iron removal dry titanium separation machine type I

-

Three-roll iron removal dry titanium separation machine type II

Permanent magnet cylinder type wet titanium separator

A high-tech enterprise with professional research and development, manufacturing and sales of mining machinery, environmental protection equipment and accessories as the main body. The company has a professional technical team and cooperates with the well-known domestic research institute, the Chinese Academy of Sciences, and independently developed new mineral processing equipment, which saves many mineral processing enterprises. Occupying space, optimizing the process, increasing production capacity and greatly reducing production costs.

Key words:

Permanent magnet cylinder type wet titanium separator

Classification:

Description

Overview

Wet titanium machine mainly adopts high-performance permanent magnet magnet material to take special production process manufacturing, installation. The wet titanium separator can replace a large number of spirals, save a lot of water, and the magnetic field strength is as high as 12000 Gauss. The newly upgraded automatic oil injection technology and material separation technology can separate a variety of minerals according to different materials. It is flexible in usability and is suitable for titanium, manganese, The extraction and separation of various weakly magnetic metals such as nickel are also suitable for the extraction and separation of zirconium and titanium.

The products selected by this wet titanium selection machine are of high grade, with the characteristics of small power consumption, simple installation, small floor area, low maintenance rate, large processing capacity and high recovery rate. This high magnetic field permanent magnet titanium machine is the company's patented products.

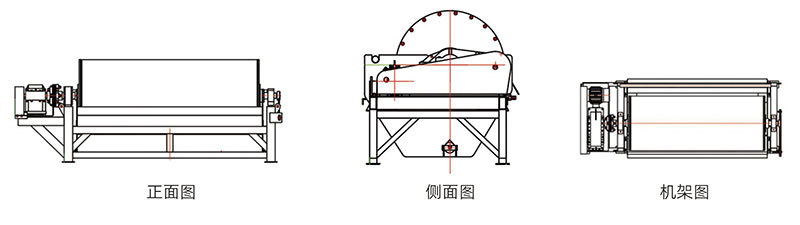

Structure diagram

Main use

The permanent magnet cylinder type wet titanium separation machine is mainly used for magnetic separation of weak magnetic substances such as titanium, manganese and nickel in granular powder materials. The wet selection method is used to select weak magnetic substances such as titanium, manganese and nickel in the selected materials, in magnetite, titanium ore, titanium magnetite, hematite, limonite, siderite, chromite, manganese ore, river sand and other enrichment of titanium, manganese, nickel and other weak magnetic material selection has a wide range of applications.

Products in Hebei, Shanxi, Shandong, Gansu, Yunnan, Inner Mongolia, Sichuan Panzhihua, Xinjiang, Liaoning and other places, with its high efficiency, energy saving, environmental protection, low price, easy installation, high safety factor and many other advantages by the majority of users. The quality and function of the products are well received by customers at home and abroad. The products are also exported to Iran, Indonesia, Mozambique and other countries, laying a solid foundation for the good development of the domestic machine manufacturing industry in foreign markets.

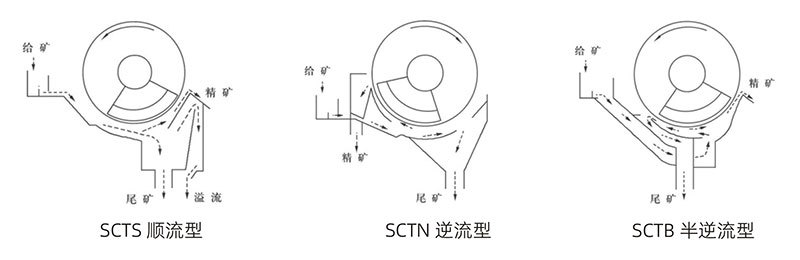

Three tank types

Technical parameters

Model specifications | Cylinder size | Speed | roller surface magnetic induction intensity | Processing capacity | Motor power | |

Cylinder diameter mm | Cylinder length mm | |||||

YGXT 1018 | 1000 | 1800 | 0-30 | According to the nature of raw ore material | 30-50 | 11 |

YGXT 1021 | 1000 | 2100 | 0-30 | 50-60 | 15 | |

YGXT 1024 | 1000 | 2400 | 0-30 | 60-70 | 18.5 | |

Application

Experiment on Separation of Zirconium and Titanium in Dry Separation of Mosan Mine

Experiment on Separation of Zirconium and Titanium in Dry Separation of Mosan Mine

Shandong Yuxiao Site Installation and Production Chart

Shandong Yuxiao Site Installation and Production Chart

Site Installation Drawing

Site Installation Drawing

Site Installation Drawing

Site Installation Drawing

Related Products

Consultation

Please leave your contact information, we will provide you with the latest product quotation information